Six Sigma

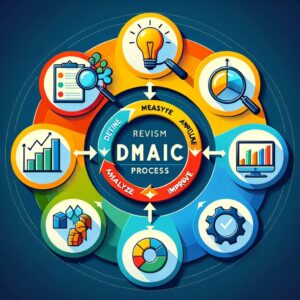

Six Sigma is a highly disciplined and data-driven approach aimed at improving the quality of processes within an organization. Developed in the 1980s at Motorola, it focuses on identifying and removing the causes of defects and minimizing variability in manufacturing and business processes. The core principles of Six Sigma involve:

- Define: Identifying the problem or project goals.

- Measure: Collecting data and understanding current performance.

- Analyze: Identifying root causes of defects.

- Improve: Implementing solutions to address these causes.

- Control: Maintaining the improvements and ensuring consistent performance.

Six Sigma uses a set of quality management methods, mainly empirical and statistical techniques, and creates a special infrastructure of people within the organization (‘Champions’, ‘Black Belts’, ‘Green Belts’, etc.) who are experts in these methods. A key aim is to ensure that improvements in quality are sustainable over the long term.

Similar Tools and Methodologies:

- Lean Management: Focuses on reducing waste within a system without sacrificing productivity, often complementing Six Sigma’s focus on quality.

- Total Quality Management (TQM): An older, broader approach than Six Sigma, TQM focuses on long-term success through customer satisfaction and encompasses all members of an organization.

- ISO 9001: An international standard for quality management systems, it provides a framework for consistent quality in products and services.

- Kaizen: A continuous improvement philosophy from Japan that focuses on small, ongoing positive changes that can lead to major improvements.

- Theory of Constraints: Concentrates on identifying and addressing the most significant limiting factor (constraint) in achieving goals, and systematically improving it.

Understanding these various methodologies can provide a broader toolkit for management consultants, enabling them to choose the most appropriate approach for their specific organizational context and objectives.